The service hotline:

0739-5051798 13975998481

News information

新闻动态

News detail

Current location:Home Page > News information > News detail

How to correctly adjust the electric device of the valve

作者:Gaopin 时间:2018-05-25 15:46:51 阅览数:2816

In the process of production and water supply in industrial enterprises, especially in urban water works, a large number of ordinary gate valves, butterfly valves, and liquid controlled butterfly valves are used to control the production of water, which is a major equipment for the water supply enterprises. The number of valves used in various valves is large. This article will discuss how to adjust the electric valve of electric valve.

The electric gate valve is composed of an electric valve and an electric valve, and is used for controlling the opening and closing of the gate valve. It can be operated on the spot and can be operated in a long distance. The valve electric device consists of an electric motor, a reducer, a torque restriction mechanism, a stroke control mechanism, a manual electric conversion mechanism, an opening indicator and an electrical controller. If the electric device of the electric gate valve is not adjusted, the light will shorten the service life of the valve; the weight leads to the fracture of the valve cast iron shell, the control of the motor burning and the serious accidents of the water flooded pump room. Therefore, in order to ensure safe and uninterrupted water supply, we must carefully adjust the electric valve of the electric valve device to ensure that the electric valve is opened and closed smoothly. The following two kinds of adjustment methods for electric gate valves are introduced.

1, adjustment of torque restriction mechanism

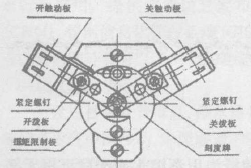

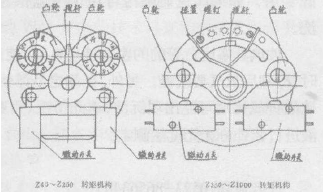

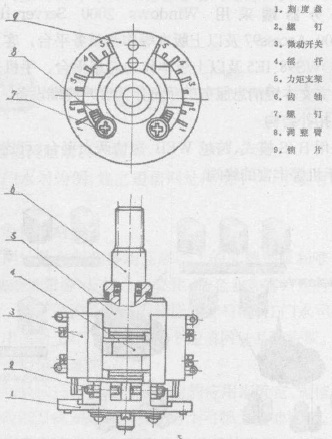

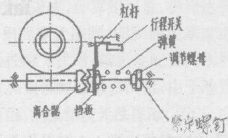

Electric gate valves are used at different locations due to the difference of water pressure difference or pressure difference at both ends of the gate. When the gate valve is closed, the torque limiting mechanism can be adjusted properly. When the hydraulic or pressure difference is low at both ends of the electric gate valve, the torque limiting mechanism should be adjusted to the lower torque. In the use of the HZ series (see Figure 1), the Z series (see Figure 2) or the ZB series (see Figure 3) valve electric device, the distance between the pullout plate and the touch plate should be adjusted to realize the torque limit mechanism. (see the details of the adjustment). The scale is marked with a scale, and the larger the scale, the greater the torque. When the electric valve gate closes, the greater the pressure difference or the difference of the air pressure between the two ends, the larger the adjusted torque value is, the less it is. The above series of adjustments are the same. When adjusting the ZD series valve electric device (see Figure 4), to unload the side cover of the box, adjust the torque limit mechanism, the tightening screw in the loosing adjustment nut, the loosening adjustment nut, the loosening button moment spring, and the looser position, and then tighten the tightening screw in the adjusting nut and fix the adjusting nut. Notice that the top of the tightening screw must fall inside the shaft slot, such as the tip is not exactly aligned with the shaft slot, so long as the adjusting nut is rotated in the direction of the compression spring, so that it is aligned to the shaft slot to tighten the screw. Then install the side cover and adjust the valve. If the torque limiting mechanism moves, the spring is too loose to move until it moves. This can make the torque limiting mechanism work under the lower torque to ensure that the electric gate valve can operate reliably when the stroke control mechanism fails, or other reasons, and the motor power is cut off to protect the valve from damage. The electric gate valves used in some places do not have to be adjusted to be too tight and adjust to the half ring (or one lap) position after manual closing, (or no water or gas is good).

Figure 1 HZ series torque limiting mechanism

Figure 2 Z series torque limiting mechanism

图3 ZB系列转矩限制机构

Figure 4 ZD series torque limiting mechanism

When the electric gate valve is installed in the place where the outlet water pressure difference (or air pressure difference) is large, the torque limiting mechanism should be adjusted to the proper opening and closing torque. If the water gate valve is installed in the pump room, the water pressure is larger when the valve is not opened after the pump is started. The greater the caliber of the gate valve is, the greater the torque is used to open the gate valve. In particular, when there is no pressure in the pipe, the unidirectional pressure of the gate valve is maximum, then the nut compression spring is adjusted to adjust to the normal opening and closing of the gate valve, and the torque restriction mechanism does not move. When using the electric gate valve in the pump house, it must be adjusted to the fully closed and full closed position when adjusting, otherwise it will easily cause damage to the sealing surface of the gate valve and cause leakage. Because the electric gate valve installed in the area is close to the water outlet of the pump, the flow speed is high and not stable. At this time, if the gate valve is not fully opened and some gate plates move before and after the flow impact, the seal surface of the gate is worn, and the leakage of the grooves will affect the service life of the valve. In addition, try to avoid using electric valve to regulate flow, otherwise it is easy to damage the sealing surface of the gate valve. In addition, in recent years, the frequency conversion speed regulation technology is developing rapidly. The frequency regulation technology of pumps should be adopted to achieve energy saving and consumption reduction and improve the efficiency of pumps.

2. "open and close" position adjustment of electric gate valve

Adjust the opening and closing of the electric gate valve. According to the adjustment requirements of all manufacturers, the valve should be manually closed to the "full closed" position or "fully open" position. According to this requirement, large calibre gate valves will be much more time-consuming and more laborious. A new adjustment method is introduced here: if we know the stem pitch of the gate valve, it is very convenient to adjust the electric valve. Now domestic production valve caliber in DN400-DN600 gate valve stem stem pitch is generally 8mm, DN600 caliber gate valve stem pitch generally 10mm. If possible, the valve stem spacing can be inquired to the gate valve manufacturer. When adjusting the valve electric device, if we know the location of the gate valve beforehand, if we know that the gate valve is in full closed position, we should first adjust the "full closed" position. First, manually turn the gate valve in the direction of opening, such as turning the valve stem half circle or circle. Then the power is pressed and the "open" button is pressed. Check the steering, if the valve button is pressed, the steering of the stem and the steering of the valve stem are consistent when the valve is opened manually, indicating that the phase sequence of the motor is the same as the direction of the electrical controller of the valve. At this time, the stroke control mechanism of the gate valve can be adjusted to the full closed position. After the full closed position is adjusted, the full open position of the gate valve can be adjusted. Set. At this time, when the gate valve is opened, counting the number of turns of the valve stem will know whether or not it is in the "full open" position. If it is DN500's electric gate valve, its stem tooth distance is 8mm, the valve stem turns on one circle to open 8mm, when the valve plate is fully open to move up 500mm, so the valve stem needs to rotate the 500/8=62.5 ring when it is fully open. At this time, press the opening of the valve button to the 63 circle valve to the "full open" position, adjust the stroke controller of the valve electric device, so that the "full open" position of the micro switch action. After that, the electric valve can be closed, opened and checked, and the adjustment will be completed. If the electric valve is in the open position before adjustment, the position should be adjusted first.

3 precautions after adjustment

One year after the use of the electric gate valve, check whether the tightening screws in the adjusting nut of the torque limiting mechanism loosen or fall off. In particular, the ZD series valve electric device (see Figure 4), some electric gate valves have occurred at the bottom of the gate valve to be broken by the top of the valve plate or the joint of the upper fixed electric device. Why do we have a torque limiting mechanism that does not move or cut off the power when the torque is torques, the reason is that the tightening screw of the adjusting nut in the torque restriction mechanism causes the adjustment nut to tighten the spring for a long time, until the dead spring is pressed, so that the torque limit mechanism is lost and does not play the protective effect and causes the electric brake. Valve damage accident. Therefore, to check once a year whether the set screws are falling off or not, if the screws are loose, they should be tightened up in time, and the reasons for the shedding should be checked and reinforced.

Manual electric switch handle requires mechanical mechanism to be flexible and easy to handle. When pulling to manual operation, it is necessary to ensure that the power is cut off to avoid accidents.

The gate valves which are seldom opened or closed for a long time should be regularly switched to ensure normal operation. (it is suggested that it is best to rotate once every March).

Contacts:Mr. Chen 13975998481

Company email:2323482529@qq.com

Company address:Shaoyang city double area industrial street river levee

Shaoyang Gaopin hydraulic valve Co., Ltd. all rights copyright

24 hour Hotline:

0739-5051798

business QQ:

2323482529